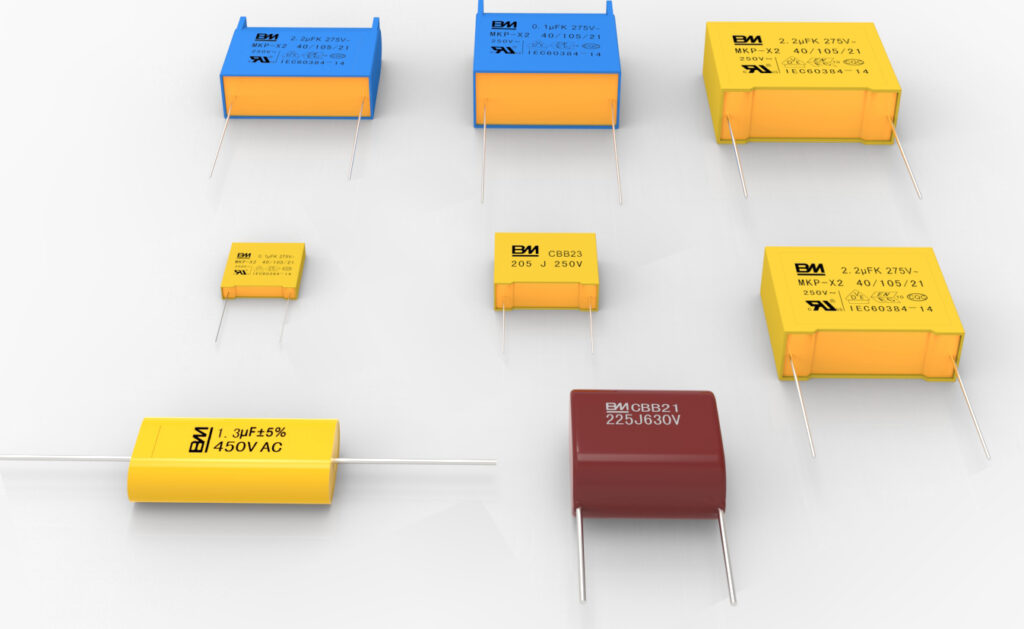

Many engineers wonder what’s the difference between the plastic box film capacitors and dipped capacitors. Let’s study the difference for these two types film capacitors from three aspects.

1.Moisture resistance ability

When the capacitors are applied in the high humidity or moisture environment, the dipped capacitors’ film element may be corroded by moisture, the metallized coating oxidized, the capacitance will decrease, the loss angle and the self-temperature will increase. The dipped polypropylene capacitors are failure to provide a reliable humidity protection, while the box plastic film capacitors are much more excellent.

Why box type capacitors work better are dipped film capacitors?

It’s because the housing of box type capacitor is the plastic materials such as PBT, ABS or PPS, while the dipped capacitors have no such housing and it’s the epoxy resin filled around the film elements. Therefore, the sealing effect of the box type capacitors are better than the dipped one.

Therefore, in terms of moisture resistance, the box plastic film capacitor is more excellent than dipped type capacitors.

2.Appearance and Dimension Consistence

The dimension tolerances of the box film capacitors are more easily to be controlled. But the dipped capacitors are very difficult to realize, since the thickness of epoxy filling cannot be controlled. There are easily to occur errors during the mass production and dimension consistence is not so good as the dipped types polypropylene capacitor.

3.Shocking Resistance Ability

There is very limited space between the dipped capacitors and PCB. When the products encounter continuous high vibration during the usage, the dipped capacitor’s cover around the pins are easy to crack, which may make moisture penetrate the film element, the metallized coating oxidized. Continuous vibration also loosens the solder joint between the pins and the metallized layers of the film element, causing short circuit or spark arcing.

But the box plastic type capacitors have the plastic housing as the support point. It’s not easy to crack between the pins and epoxy resin, nor the solder joint on the metallized layer of the film elements and the pins loose. The performance is better than that of the dipped product.

Let’s make the conclusion, it’s strongly suggested customers to choose box metallized polypropylene film capacitor instead of dipped film capacitors especially when the application is in the high humidity or moisture working ambience.

BM capacitors are always working to offer the most professional suggestions on customized polypropylene film capacitors.

For more product details, can visit www.bm-cap.com.